Wet type silica sand processing line

Suitable for quartz sand, potassium albite, etc.

- Product Description

- Advantage Features

- Working principle

- Technical parameters

- Successful Cases

-

- Commodity name: Wet type silica sand processing line

Suitable for quartz sand, potassium albite, etc.

Suitable for quartz sand, potassium albite, etc. The use of reasonable process equipment greatly saves power consumption and realizes zero discharge of sewage and dust. It has the advantages of large output, high purity and no pollution, and stable and reliable process.

[material particle size]: 20-150 mesh

[production capacity]: 10-50 tons/hour

【Application】: glass, ceramic industry

[applicable materials]: quartz, feldspar, andalusite, etcProduct advantages

Mature technology, energy saving and environmental protection! High purity pollution-free

The use of reasonable process equipment greatly saves power consumption and realizes zero discharge of sewage and dust.Simple operation and high degree of automation

The production line process is carefully designed and the circuit control system is adopted, which not only saves labor but also reduces the operating threshold of the production line.Large output, uniform product size, higher sand rate

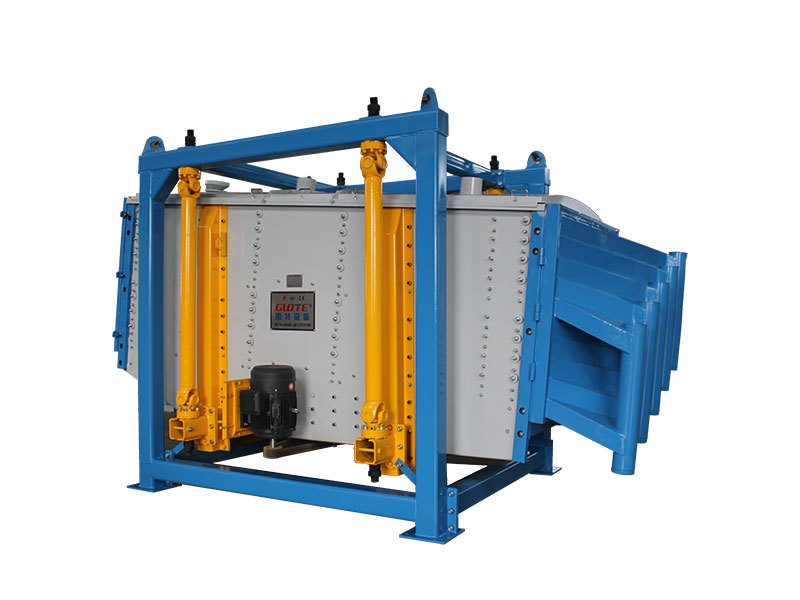

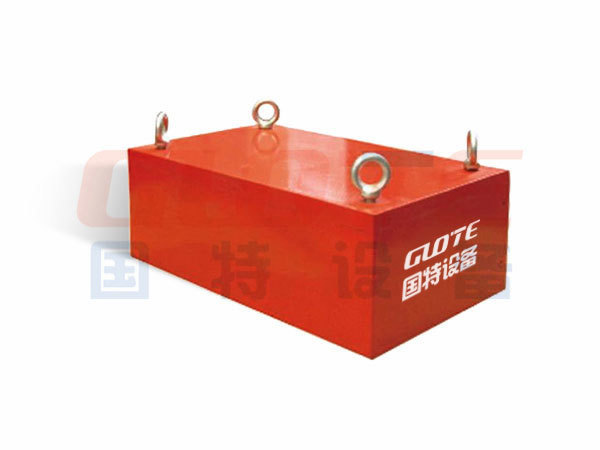

The whole production process through the cylinder screen, blocked, classifier multiple classification, not only improve the efficiency of the production line to reduce the loss of raw ore, control the content of tailings.High product quality, can effectively reduce the iron content of quartz sand

We have rich experience in quartz sand production line, the whole process is not only equipped with iron removal equipment, but also controlled at the source to reduce the pollution of sand in the processing process as much as possible.Working principle

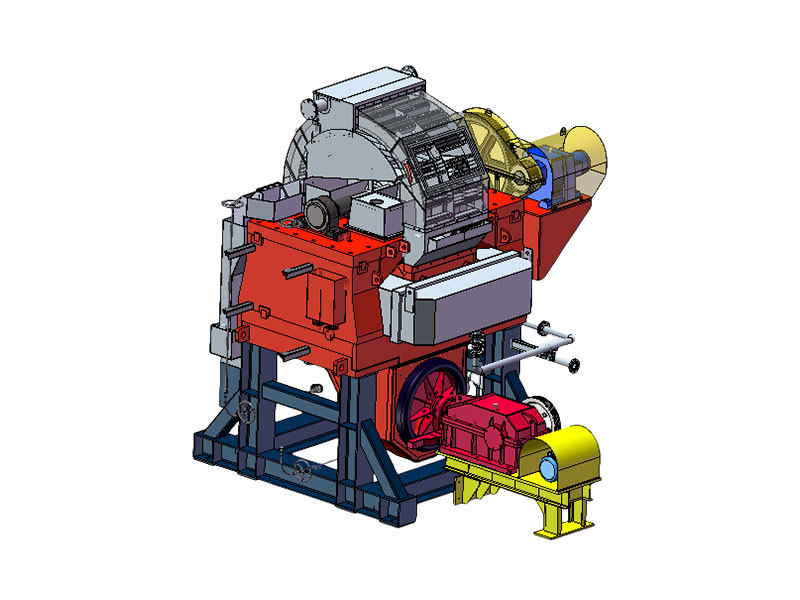

The general process flow is: "raw ore-coarse crushing-medium crushing-pre-screening-grinding-desliming-coarse grain classification-desliming-plate magnetic separator rough separation-vertical ring high gradient magnetic separator selection-fine grain classification-dehydration" process flow for the production of wet quartz sand.

Production process: the forklift truck feeds the raw ore into the silo, a conveyor is placed at the tail of the silo, and the raw ore coming out of the tail is evenly fed into the jaw crusher (coarse crushing) directly below through the conveyor through the vibrating feeder for preliminary crushing. Then, the coarse material produced is transported by the conveyor to the fine crusher for further crushing, and the finely crushed stone is fed into the vibrating screen to screen out two kinds of stones and stones of different sizes, and the large stones exceeding the specifications are returned to the fine crusher for crushing again. The material under the sieve enters the rod mill, and the material from the rod mill is graded by the cylindrical sieve and returned to the rod mill on the sieve. The material under the screen enters the blocked settling machine and the hydraulic classifier for classification. After grading, the finished product is de-ironized by high field strength plate magnetic separator and vertical ring high gradient strong magnetic separator. The iron-removed sand is dewatered by the desliming hopper and then driven into the sand silo.

Product Description

Suitable for quartz sand, potassium albite, etc. The use of reasonable process equipment greatly saves power consumption and realizes zero discharge of sewage and dust. It has the advantages of large output, high purity and no pollution, and stable and reliable process.

[material particle size]: 20-150 mesh

[production capacity]: 10-50 tons/hour

【Application】: glass, ceramic industry

[applicable materials]: quartz, feldspar, andalusite, etc

Product advantages

Mature technology, energy saving and environmental protection! High purity pollution-free

The use of reasonable process equipment greatly saves power consumption and realizes zero discharge of sewage and dust.

Simple operation and high degree of automation

The production line process is carefully designed and the circuit control system is adopted, which not only saves labor but also reduces the operating threshold of the production line.

Large output, uniform product size, higher sand rate

The whole production process through the cylinder screen, blocked, classifier multiple classification, not only improve the efficiency of the production line to reduce the loss of raw ore, control the content of tailings.

High product quality, can effectively reduce the iron content of quartz sand

We have rich experience in quartz sand production line, the whole process is not only equipped with iron removal equipment, but also controlled at the source to reduce the pollution of sand in the processing process as much as possible.

Working principle

The general process flow is: "raw ore-coarse crushing-medium crushing-pre-screening-grinding-desliming-coarse grain classification-desliming-plate magnetic separator rough separation-vertical ring high gradient magnetic separator selection-fine grain classification-dehydration" process flow for the production of wet quartz sand.

Production process: the forklift truck feeds the raw ore into the silo, a conveyor is placed at the tail of the silo, and the raw ore coming out of the tail is evenly fed into the jaw crusher (coarse crushing) directly below through the conveyor through the vibrating feeder for preliminary crushing. Then, the coarse material produced is transported by the conveyor to the fine crusher for further crushing, and the finely crushed stone is fed into the vibrating screen to screen out two kinds of stones and stones of different sizes, and the large stones exceeding the specifications are returned to the fine crusher for crushing again. The material under the sieve enters the rod mill, and the material from the rod mill is graded by the cylindrical sieve and returned to the rod mill on the sieve. The material under the screen enters the blocked settling machine and the hydraulic classifier for classification. After grading, the finished product is de-ironized by high field strength plate magnetic separator and vertical ring high gradient strong magnetic separator. The iron-removed sand is dewatered by the desliming hopper and then driven into the sand silo.

Advantage Features

Working principle

Technical parameters

Successful Cases

GUOTE MINING

Your reliable supplier

Mine Purification Equipment Engineering Laboratory. The company's products have passed ISO9001 quality system certification, environmental management system certification, occupational health and safety management system certification, EU ce certification, and dozens of national patents. Products are exported to South Korea, India, Southeast Asia, Africa and other countries and regions.

Get A Quote

If you have any questions, please feel free to leave us a message at any time