Silicon powder production line

Mineral processing, chemical, pharmaceutical, building materials, plate with quartz powder, etc.

- Product Description

- Advantage Features

- Working principle

- Technical parameters

- Successful Cases

-

- Commodity name: Silicon powder production line

Mineral processing, chemical, pharmaceutical, building materials, plate with quartz powder, etc.

Mineral processing, chemical, pharmaceutical, building materials, plate with quartz powder, etc. This product can be used to produce 200-1250 mesh high purity quartz powder, the product has the advantages of high purity, good whiteness, stable particle size and so on. The whole production line can realize automatic control and the equipment runs stably.

Application areas:

Mineral processing, chemical industry, building materials, quartz powder for plate, etc. -

1. High purity wear protection

The whole production process of high purity wear protection, according to the differences in production conditions, ball mill lining can be equipped with ceramic lining or quartz lining, grinding media can choose ceramic ball or quartz ball, the whole classification system using ceramic protection, so that the whole process does not contact metal, to ensure the purity of the product and prolong the service life of the equipment.

2. Reduce wear

The blade of grading impeller adopts polymer wear-resistant material, which effectively solves the wear problem of grading impeller. Simple equipment operation

3. Simple equipment operation

PLC automatic control can be designed according to the requirements, from grinding → grading → packaging, the whole process of automatic control, reduce labor intensity, save production costs.

4. Low limit to reduce energy consumption

Theory and practice to optimize the system configuration, low limit to reduce energy consumption, the system of each dust point of the scientific dust removal design, effective control of dust spillover, in line with the national environmental protection requirements.

5. International standard production line

According to the different requirements of customers, customized design and manufacturing, equipment operation is stable and reliable.

6. High product purity

Good whiteness, stable particle size, in line with quartz plate filling material standards. -

Raw materials with less than -10 mesh are evenly fed into the mill bin by the feeding device through the hollow shaft screw. The bin is equipped with a ceramic lining plate and steel jade balls of different specifications are installed. The rotation of the cylinder generates centrifugal force to bring the media balls to a certain height and then fall down, which produces impact and grinding effect on the materials. The powder that meets the requirements is discharged through the discharge grate plate to complete the grinding operation. The ground material enters the classifier from the feed inlet. By adjusting the rotating speed of the classification wheel (frequency conversion control, stepless speed regulation) and matching with reasonable secondary air inlet, a reasonable and stable gas-solid two-phase flow is formed in the classification area. The centrifugal force generated by the rotation of the classification wheel and the attractive force generated by the negative pressure of the induced draft fan are used to realize the effective classification of the material. The coarse particles are returned to the ball mill by the coarse material return device to continue grinding, and the finished product is packaged by the automatic packaging machine. The whole system is equipped with a dust collector, which adopts advanced electromagnetic pulse automatic dust removal. After the gas carrying dust enters the dust collector, the dust is filtered by the filter bag, and the dust attached to the outer surface of the filter bag is scattered at the bottom under the action of the pulse blowback gas. The filtered clean gas is discharged into the atmosphere through the fan.

-

Model

Ball mill model

Classifier model

Total power

Processing capacity

fineness

Grading accuracy

Filtration area

dust concentration

working system

GMF-100

Φ1500*5700

GF100

≤ 145

1.2-1.8

5-50

D97

≥70

≤ 40

Continuous

GMF-200

Φ1830*7000

GF200

≤ 225

3.5-4

5-50

D97

≥ 100

≤ 40

GMF-400

Φ2200*7000

GF400

≤ 345

5-6

5-50

D97

≥ 120

≤ 40

GMF-500

Φ2200*7500

GF500

≤500

5-7

5-50

D97

≥ 200

≤ 40

GMF-600

Φ2400*7500

GF600

≤ 550

7-9

5-50

D97

≥ 300

≤ 40

GMF-800

Φ2600*8000

GF800

≤ 665

8-12

5-50

D97

≥ 350

≤ 40

GMF-1000

Φ2800*8000

GF1000

≤ 780

10-15

5-50

D97

≥ 400

≤ 40

GMF-1200

Φ3200*9000

GF1200

≤1200

15-20

5-50

D97

≥ 500

≤ 40

-

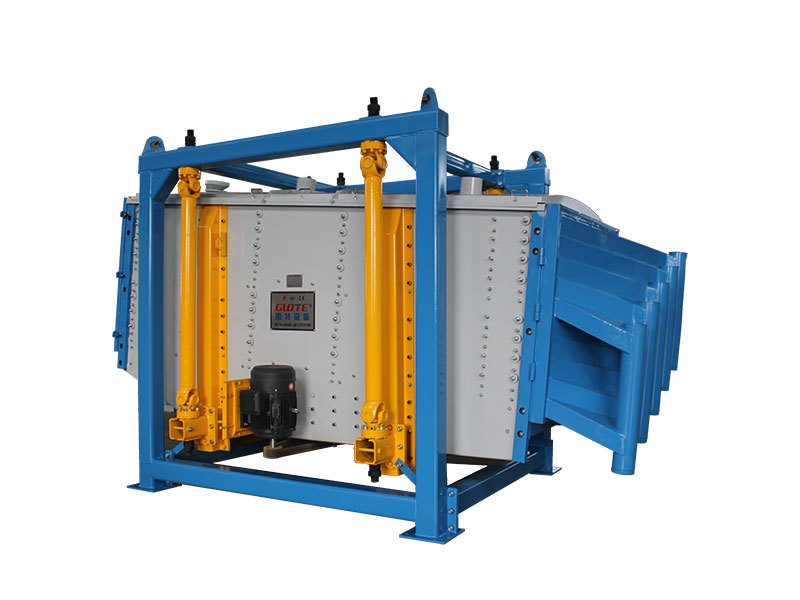

Product Description

Mineral processing, chemical, pharmaceutical, building materials, plate with quartz powder, etc. This product can be used to produce 200-1250 mesh high purity quartz powder, the product has the advantages of high purity, good whiteness, stable particle size and so on. The whole production line can realize automatic control and the equipment runs stably.

Application areas:

Mineral processing, chemical industry, building materials, quartz powder for plate, etc.

Advantage Features

1. High purity wear protection

The whole production process of high purity wear protection, according to the differences in production conditions, ball mill lining can be equipped with ceramic lining or quartz lining, grinding media can choose ceramic ball or quartz ball, the whole classification system using ceramic protection, so that the whole process does not contact metal, to ensure the purity of the product and prolong the service life of the equipment.

2. Reduce wear

The blade of grading impeller adopts polymer wear-resistant material, which effectively solves the wear problem of grading impeller. Simple equipment operation

3. Simple equipment operation

PLC automatic control can be designed according to the requirements, from grinding → grading → packaging, the whole process of automatic control, reduce labor intensity, save production costs.

4. Low limit to reduce energy consumption

Theory and practice to optimize the system configuration, low limit to reduce energy consumption, the system of each dust point of the scientific dust removal design, effective control of dust spillover, in line with the national environmental protection requirements.

5. International standard production line

According to the different requirements of customers, customized design and manufacturing, equipment operation is stable and reliable.

6. High product purity

Good whiteness, stable particle size, in line with quartz plate filling material standards.

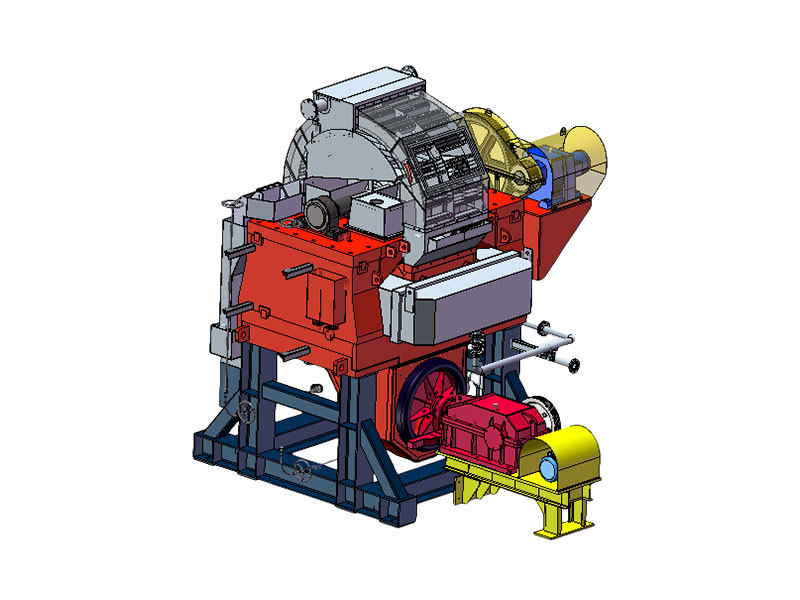

Working principle

Raw materials with less than -10 mesh are evenly fed into the mill bin by the feeding device through the hollow shaft screw. The bin is equipped with a ceramic lining plate and steel jade balls of different specifications are installed. The rotation of the cylinder generates centrifugal force to bring the media balls to a certain height and then fall down, which produces impact and grinding effect on the materials. The powder that meets the requirements is discharged through the discharge grate plate to complete the grinding operation. The ground material enters the classifier from the feed inlet. By adjusting the rotating speed of the classification wheel (frequency conversion control, stepless speed regulation) and matching with reasonable secondary air inlet, a reasonable and stable gas-solid two-phase flow is formed in the classification area. The centrifugal force generated by the rotation of the classification wheel and the attractive force generated by the negative pressure of the induced draft fan are used to realize the effective classification of the material. The coarse particles are returned to the ball mill by the coarse material return device to continue grinding, and the finished product is packaged by the automatic packaging machine. The whole system is equipped with a dust collector, which adopts advanced electromagnetic pulse automatic dust removal. After the gas carrying dust enters the dust collector, the dust is filtered by the filter bag, and the dust attached to the outer surface of the filter bag is scattered at the bottom under the action of the pulse blowback gas. The filtered clean gas is discharged into the atmosphere through the fan.

Technical parameters

|

Model |

Ball mill model |

Classifier model |

Total power |

Processing capacity |

fineness |

Grading accuracy |

Filtration area |

dust concentration |

working system |

|

GMF-100 |

Φ1500*5700 |

GF100 |

≤ 145 |

1.2-1.8 |

5-50 |

D97 |

≥70 |

≤ 40 |

Continuous |

|

GMF-200 |

Φ1830*7000 |

GF200 |

≤ 225 |

3.5-4 |

5-50 |

D97 |

≥ 100 |

≤ 40 |

|

|

GMF-400 |

Φ2200*7000 |

GF400 |

≤ 345 |

5-6 |

5-50 |

D97 |

≥ 120 |

≤ 40 |

|

|

GMF-500 |

Φ2200*7500 |

GF500 |

≤500 |

5-7 |

5-50 |

D97 |

≥ 200 |

≤ 40 |

|

|

GMF-600 |

Φ2400*7500 |

GF600 |

≤ 550 |

7-9 |

5-50 |

D97 |

≥ 300 |

≤ 40 |

|

|

GMF-800 |

Φ2600*8000 |

GF800 |

≤ 665 |

8-12 |

5-50 |

D97 |

≥ 350 |

≤ 40 |

|

|

GMF-1000 |

Φ2800*8000 |

GF1000 |

≤ 780 |

10-15 |

5-50 |

D97 |

≥ 400 |

≤ 40 |

|

|

GMF-1200 |

Φ3200*9000 |

GF1200 |

≤1200 |

15-20 |

5-50 |

D97 |

≥ 500 |

≤ 40 |

Successful Cases

GUOTE MINING

Your reliable supplier

Mine Purification Equipment Engineering Laboratory. The company's products have passed ISO9001 quality system certification, environmental management system certification, occupational health and safety management system certification, EU ce certification, and dozens of national patents. Products are exported to South Korea, India, Southeast Asia, Africa and other countries and regions.

Get A Quote

If you have any questions, please feel free to leave us a message at any time