Wet plate magnetic separator

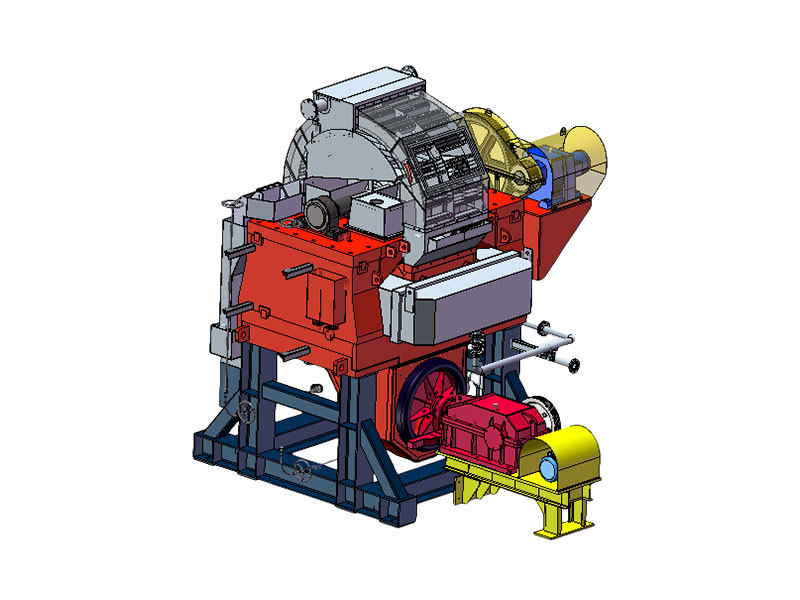

This product is a high-gradient, high-field magnetic separation equipment newly developed by our company.

- Product Description

- Advantage Features

- Working principle

- Technical parameters

- Successful Cases

-

- Commodity name: Wet plate magnetic separator

This product is a high-gradient, high-field magnetic separation equipment newly developed by our company.

This product is a high-gradient, high-field magnetic separation equipment newly developed by our company. It is mainly suitable for the removal of iron from fine-grained non-metallic minerals less than 1.2mm, such as quartz, feldspar, nepheline ore, and kaolin. It can also be used for the wet separation of red ore (hematite, limonite, siderite, etc.), manganese ore, ilmenite, wolframite and other weakite.

-

1, the selection of high-performance NdFeB magnetic material, magnetic circuit design is unique, the highest surface magnetic field can reach 15000GS, enough to high gradient electromagnetic separator comparable.

2. Compared with other permanent magnetic separators, the magnetic field scanning area is large and the iron removal effect is good.

3. The slope of the board surface is adjustable, and the best iron removal effect can be achieved by adjusting the slope according to the material condition.

4. The belt speed can be adjusted by frequency conversion, and the belt speed can be adjusted according to the material condition to achieve better iron removal effect.

5. The use of wear-resistant canvas as the conveyor belt greatly increases the service life of the conveyor belt.

6. Compared with other high gradient vertical ring magnetic separator, energy saving.

7. The ore is equipped with a uniform feeding device, and the ore is equipped with a device for automatically cleaning adsorbed magnetic substances. -

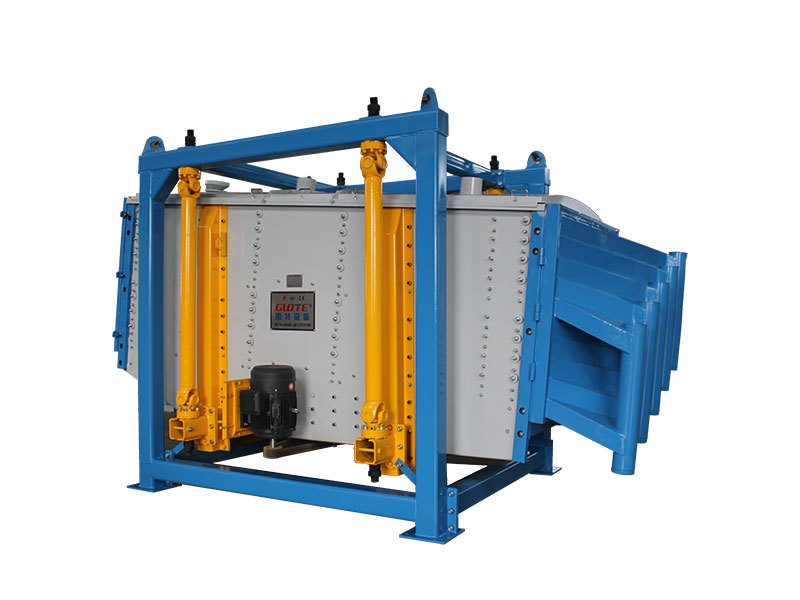

The slurry enters the uniform distribution device of the magnetic separator through the feeding pipe. After being fully dispersed, the slurry falls on the unloading iron belt on the upper part of the magnetic plate. Under the action of gravity, the slurry flows downward along the inclined direction of the magnetic plate. The ferromagnetic substances contained in the slurry are firmly adsorbed on the unloading iron belt under the strong magnetic field provided by the magnetic plate. The unloading iron belt rotates along the inclined upper part of the magnetic plate driven by the motor, at the same time, the adsorbed ferromagnetic materials are brought into the iron unloading area. Ferromagnetic materials enter the tailings hopper to be collected under the flushing of flushing water, and the non-magnetic slurry continues to flow downward along the magnetic plate and flows into the concentrate hopper to be collected centrally.

-

Model

Capacity (t/h)

Magnetic field strength (GS)

pulp concentration

Belt speed (r/min)

Motor power (kw)

Weight (t)

Plate magnetic effective size (mm)

GTGB-815

8-10

15000

10%-30%

2-8

2.2

1.2

800X1500

GTGB-1020

15-20

15000

10%-30%

2-8

2.2

1.6

1000X2000

GTGB-1520

20-25

15000

10%-30%

2-8

2.2

3

1500X2000

GTGB-2025

25-30

15000

10%-30%

2-8

3

3.6

2000X2500

GTGB-2230

30-35

15000

10%-30%

2-8

4

4.5

2200X3000

GTGB-2530

35-40

15000

10%-30%

2-8

4

5.6

2500X3000

GTGB-3025

40-50

15000

10%-30%

2-8

4

6.7

3000X2500

-

Product Description

This product is a high-gradient, high-field magnetic separation equipment newly developed by our company. It is mainly suitable for the removal of iron from fine-grained non-metallic minerals less than 1.2mm, such as quartz, feldspar, nepheline ore, and kaolin. It can also be used for the wet separation of red ore (hematite, limonite, siderite, etc.), manganese ore, ilmenite, wolframite and other weakite.

Advantage Features

1, the selection of high-performance NdFeB magnetic material, magnetic circuit design is unique, the highest surface magnetic field can reach 15000GS, enough to high gradient electromagnetic separator comparable.

2. Compared with other permanent magnetic separators, the magnetic field scanning area is large and the iron removal effect is good.

3. The slope of the board surface is adjustable, and the best iron removal effect can be achieved by adjusting the slope according to the material condition.

4. The belt speed can be adjusted by frequency conversion, and the belt speed can be adjusted according to the material condition to achieve better iron removal effect.

5. The use of wear-resistant canvas as the conveyor belt greatly increases the service life of the conveyor belt.

6. Compared with other high gradient vertical ring magnetic separator, energy saving.

7. The ore is equipped with a uniform feeding device, and the ore is equipped with a device for automatically cleaning adsorbed magnetic substances.

Working principle

The slurry enters the uniform distribution device of the magnetic separator through the feeding pipe. After being fully dispersed, the slurry falls on the unloading iron belt on the upper part of the magnetic plate. Under the action of gravity, the slurry flows downward along the inclined direction of the magnetic plate. The ferromagnetic substances contained in the slurry are firmly adsorbed on the unloading iron belt under the strong magnetic field provided by the magnetic plate. The unloading iron belt rotates along the inclined upper part of the magnetic plate driven by the motor, at the same time, the adsorbed ferromagnetic materials are brought into the iron unloading area. Ferromagnetic materials enter the tailings hopper to be collected under the flushing of flushing water, and the non-magnetic slurry continues to flow downward along the magnetic plate and flows into the concentrate hopper to be collected centrally.

Technical parameters

|

Model |

Capacity (t/h) |

Magnetic field strength (GS) |

pulp concentration |

Belt speed (r/min) |

Motor power (kw) |

Weight (t) |

Plate magnetic effective size (mm) |

|

GTGB-815 |

8-10 |

15000 |

10%-30% |

2-8 |

2.2 |

1.2 |

800X1500 |

|

GTGB-1020 |

15-20 |

15000 |

10%-30% |

2-8 |

2.2 |

1.6 |

1000X2000 |

|

GTGB-1520 |

20-25 |

15000 |

10%-30% |

2-8 |

2.2 |

3 |

1500X2000 |

|

GTGB-2025 |

25-30 |

15000 |

10%-30% |

2-8 |

3 |

3.6 |

2000X2500 |

|

GTGB-2230 |

30-35 |

15000 |

10%-30% |

2-8 |

4 |

4.5 |

2200X3000 |

|

GTGB-2530 |

35-40 |

15000 |

10%-30% |

2-8 |

4 |

5.6 |

2500X3000 |

|

GTGB-3025 |

40-50 |

15000 |

10%-30% |

2-8 |

4 |

6.7 |

3000X2500 |

Successful Cases

GUOTE MINING

Your reliable supplier

Mine Purification Equipment Engineering Laboratory. The company's products have passed ISO9001 quality system certification, environmental management system certification, occupational health and safety management system certification, EU ce certification, and dozens of national patents. Products are exported to South Korea, India, Southeast Asia, Africa and other countries and regions.

Get A Quote

If you have any questions, please feel free to leave us a message at any time