Vertical ring high gradient magnetic separator

At present, the use of strong magnetic magnetic separation equipment.

- Product Description

- Advantage Features

- Working principle

- Technical parameters

- Successful Cases

-

- Commodity name: Vertical ring high gradient magnetic separator

At present, the use of strong magnetic magnetic separation equipment.

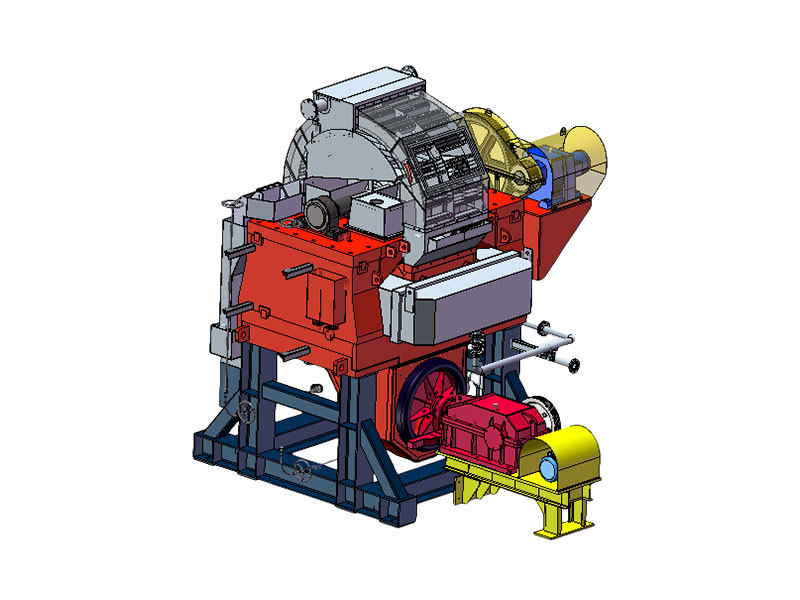

At present, the use of strong magnetic magnetic separation equipment. The machine adopts rotary ring vertical rotation, recoil concentrate, and is equipped with a high-frequency vibration mechanism. It has the advantages of large enrichment ratio, high adaptability to ore particle size, concentration and grade fluctuation, good work efficiency, convenient operation and maintenance, etc.

Application areas:

This product is suitable for wet separation of -1.2mm (-200 mesh accounts for 30-100) fine red ore (hematite, limonite, siderite, etc.), manganese ore, ilmenite, wolframite and other weakly magnetic metal ores, separation of black and white tungsten, separation of wolframite and cassiterite, and also for iron removal and purification of non-metal ores such as quartz, feldspar, nepheline and kaolin. -

1. Unique magnetic medium with high induced magnetic field: the magnetic medium adopts the patented product developed by the company, which can generate high gradient magnetic field, and the induced field strength can reach more than 20000 Gauss.

2, oil-water composite double cooling mode is the national special equipment vertical ring high gradient magnetic separator cooling mode, the use of oil-water heat exchange principle, with flushing mineral water quickly take away the heat generated by the coil, so that the coil temperature rise is less than 25 ° C, so that the magnetic field is more stable.

3. The vertical ring high gradient magnetic separator is equipped with fault diagnosis system and remote control system, which realizes the intelligent operation control of the equipment.

4. According to the characteristics of different materials, pulse device can be selected, which has the characteristics of good ore flushing effect, good sorting effect and water saving. -

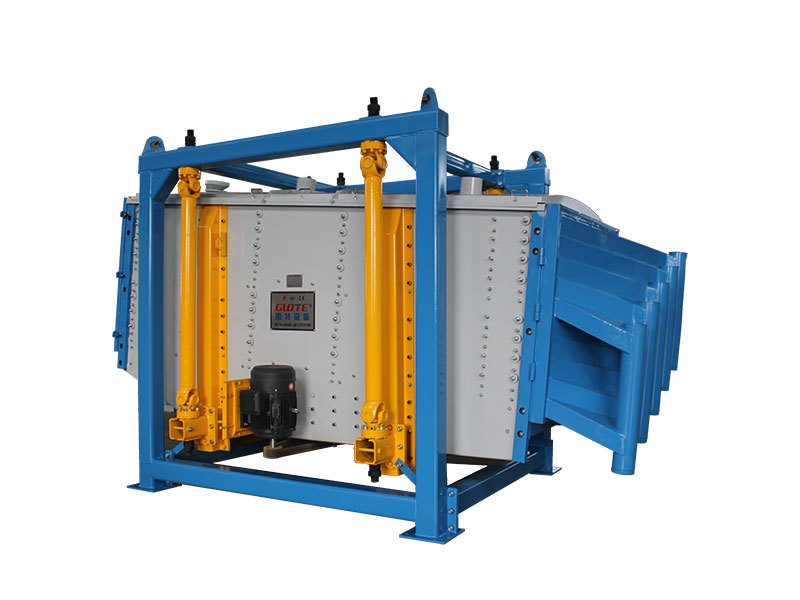

The slurry enters the ore hopper through the feeding pipe, and flows through the rotary ring along the upper magnetic field gap. The induction magnetic medium composed of high magnetic permeability stainless steel rods in the rotary ring is magnetized in the background magnetic field. The surface of the magnetic medium forms a high gradient magnetic field, and the magnetic particles in the slurry are adsorbed on the surface of the magnetic medium. With the rotation of the rotary ring, the magnetic materials are washed into the concentrate hopper, the non-magnetic particles flow into the tailings hopper along the gap under the magnetic pole and are discharged away to realize the separation of materials. The magnetic medium at the lower part of the rotating ring is immersed in the slurry liquid surface. While the slurry is injected, the stroke box installed on one side of the tailings box continuously reciprocates, causing the slurry in the sorting chamber to fluctuate up and down through the tympanic membrane. The pulsating fluid force keeps the ore particle group in a loose state during the sorting process, thus effectively removing impurities in the particle group and significantly improving the grade of concentrate.

-

Model

GTLH500T

GTLH750T

GTLH1000T

GTLH1250T

GTLH1500T

GTLH1750T

GTLH2000T

GTLH2500T

GTLH3000T

GTLH3500T

GTLH4000T

GTLH4500T

GTLH5000T

Rated background magnetic field (T)

1T/1.4T/(1.8T)

medium induced magnetic field

1.5T/2.1T/(2.7T) Constant current continuously adjustable

Coil cooling method

oil-water compound cooling

Rated excitation power (kw)

22/35/55

24/38/60

26/40/70

28/42/95

32/45/102

37/55/110

45/65/120

60/76/140

72/106/180

93/130/200

102/140/220

110/145/240

120/155/270

Dry ore treatment capacity (t/h)

0.06~0.5

0.5~1.2

4~7

10~20

20~30

30~50

50~80

80~120

120~180

180~270

300~450

450~600

500~700

Pulp passing capacity (m3/h)

0.25~1.2

1~3

12.5~20

20~50

50~100

75~150

100~200

200~400

350~650

550~1000

750~1400

1100~1700

1400~2000

Exciter current (A)

55/95/137

60/100/150

65/110/160

85/125/170

110/140/180

130/150/190

140/180/260

165/206/280

185/250/350

205/330/400

256/345/450

262/353/480

270/360/540

Concentration of ore feed (%)

10~35%

feed grain size

-1

-1.2

Rotary speed (r/min)

1~4 (variable frequency adjustable)

Outer diameter of swivel (mm)

φ500

φ750

φ1000

φ1250

φ1500

φ1750

φ2000

φ2500

φ3000

φ3500

φ4000

φ4500

φ5000

Power of swivel motor (kw)

0.18

0.75

1.1

1.5

3

4

5.5

11

18.5

30

37

45

55

Oil pump power (kw)

4Kw

5.5Kw

Pulsating motor power (kw)

0.55

1.5

2.2

3

4

4

7.5

11

18.5

30

37

45

55

Pulsation stroke (mm)

0-30 (mechanically adjustable)

Pulsation stroke (times/min)

0-300 (variable frequency adjustable)

Exciter voltage (DCV)

0-512 (varies with current)

Ore unloading water pressure (Mpa)

0.2~0.4

Water consumption for unloading (m3/h)

0.65~1.4

1.4~2.5

8~12

12~20

20~30

30~50

50~100

100~150

150~200

250~350

350~500

500~650

550~800

Larger part weight (t)

2/3.2/4.5

2.5/3.2/4

3/4.2/5

4/6/6.8

6.5/12/15

8.5/15/17

20/24/28

24/26/28

33/36/39

50/52/55

68/75/85

70/78/82

78/80/85

Overall dimension (mm)

Long

1650

2000

2650

2880

3430

3320

4200

3660

4410

4900

5470

5980

7000

1800

2600

2850

3420

3600

3980

4350

5100

5030

6490

6200

6160

7500

1950

2900

2520

3580

3750

4120

4650

5400

5590

7000

6930

6270

8000

Wide

1500

2270

2350

2900

3680

3800

4690

4690

5540

5500

6240

6630

8100

1800

2860

3000

3280

3850

4260

4870

5930

5650

7000

7500

7830

8300

2000

3200

3600

3650

4350

4770

4950

5520

5780

8200

8760

7210

8600

High

1250

2100

2450

2860

3410

3800

4150

5290

6450

6950

8400

9200

9400

1320

2400

2630

3000

3650

4130

4300

5450

6500

7400

8600

9480

9650

1550

2600

2490

3300

3800

4300

4510

5760

6550

7950

8900

9600

9800

-

Product Description

At present, the use of strong magnetic magnetic separation equipment. The machine adopts rotary ring vertical rotation, recoil concentrate, and is equipped with a high-frequency vibration mechanism. It has the advantages of large enrichment ratio, high adaptability to ore particle size, concentration and grade fluctuation, good work efficiency, convenient operation and maintenance, etc.

Application areas:

This product is suitable for wet separation of -1.2mm (-200 mesh accounts for 30-100) fine red ore (hematite, limonite, siderite, etc.), manganese ore, ilmenite, wolframite and other weakly magnetic metal ores, separation of black and white tungsten, separation of wolframite and cassiterite, and also for iron removal and purification of non-metal ores such as quartz, feldspar, nepheline and kaolin.

Advantage Features

1. Unique magnetic medium with high induced magnetic field: the magnetic medium adopts the patented product developed by the company, which can generate high gradient magnetic field, and the induced field strength can reach more than 20000 Gauss.

2, oil-water composite double cooling mode is the national special equipment vertical ring high gradient magnetic separator cooling mode, the use of oil-water heat exchange principle, with flushing mineral water quickly take away the heat generated by the coil, so that the coil temperature rise is less than 25 ° C, so that the magnetic field is more stable.

3. The vertical ring high gradient magnetic separator is equipped with fault diagnosis system and remote control system, which realizes the intelligent operation control of the equipment.

4. According to the characteristics of different materials, pulse device can be selected, which has the characteristics of good ore flushing effect, good sorting effect and water saving.

Working principle

The slurry enters the ore hopper through the feeding pipe, and flows through the rotary ring along the upper magnetic field gap. The induction magnetic medium composed of high magnetic permeability stainless steel rods in the rotary ring is magnetized in the background magnetic field. The surface of the magnetic medium forms a high gradient magnetic field, and the magnetic particles in the slurry are adsorbed on the surface of the magnetic medium. With the rotation of the rotary ring, the magnetic materials are washed into the concentrate hopper, the non-magnetic particles flow into the tailings hopper along the gap under the magnetic pole and are discharged away to realize the separation of materials. The magnetic medium at the lower part of the rotating ring is immersed in the slurry liquid surface. While the slurry is injected, the stroke box installed on one side of the tailings box continuously reciprocates, causing the slurry in the sorting chamber to fluctuate up and down through the tympanic membrane. The pulsating fluid force keeps the ore particle group in a loose state during the sorting process, thus effectively removing impurities in the particle group and significantly improving the grade of concentrate.

Technical parameters

|

Model |

GTLH500T |

GTLH750T |

GTLH1000T |

GTLH1250T |

GTLH1500T |

GTLH1750T |

GTLH2000T |

GTLH2500T |

GTLH3000T |

GTLH3500T |

GTLH4000T |

GTLH4500T |

GTLH5000T |

|

|

Rated background magnetic field (T) |

1T/1.4T/(1.8T) |

|||||||||||||

|

medium induced magnetic field |

1.5T/2.1T/(2.7T) Constant current continuously adjustable |

|||||||||||||

|

Coil cooling method |

oil-water compound cooling |

|||||||||||||

|

Rated excitation power (kw) |

22/35/55 |

24/38/60 |

26/40/70 |

28/42/95 |

32/45/102 |

37/55/110 |

45/65/120 |

60/76/140 |

72/106/180 |

93/130/200 |

102/140/220 |

110/145/240 |

120/155/270 |

|

|

Dry ore treatment capacity (t/h) |

0.06~0.5 |

0.5~1.2 |

4~7 |

10~20 |

20~30 |

30~50 |

50~80 |

80~120 |

120~180 |

180~270 |

300~450 |

450~600 |

500~700 |

|

|

Pulp passing capacity (m3/h) |

0.25~1.2 |

1~3 |

12.5~20 |

20~50 |

50~100 |

75~150 |

100~200 |

200~400 |

350~650 |

550~1000 |

750~1400 |

1100~1700 |

1400~2000 |

|

|

Exciter current (A) |

55/95/137 |

60/100/150 |

65/110/160 |

85/125/170 |

110/140/180 |

130/150/190 |

140/180/260 |

165/206/280 |

185/250/350 |

205/330/400 |

256/345/450 |

262/353/480 |

270/360/540 |

|

|

Concentration of ore feed (%) |

10~35% |

|||||||||||||

|

feed grain size |

-1 |

-1.2 |

||||||||||||

|

Rotary speed (r/min) |

1~4 (variable frequency adjustable) |

|||||||||||||

|

Outer diameter of swivel (mm) |

φ500 |

φ750 |

φ1000 |

φ1250 |

φ1500 |

φ1750 |

φ2000 |

φ2500 |

φ3000 |

φ3500 |

φ4000 |

φ4500 |

φ5000 |

|

|

Power of swivel motor (kw) |

0.18 |

0.75 |

1.1 |

1.5 |

3 |

4 |

5.5 |

11 |

18.5 |

30 |

37 |

45 |

55 |

|

|

Oil pump power (kw) |

4Kw |

5.5Kw |

||||||||||||

|

Pulsating motor power (kw) |

0.55 |

1.5 |

2.2 |

3 |

4 |

4 |

7.5 |

11 |

18.5 |

30 |

37 |

45 |

55 |

|

|

Pulsation stroke (mm) |

0-30 (mechanically adjustable) |

|||||||||||||

|

Pulsation stroke (times/min) |

0-300 (variable frequency adjustable) |

|||||||||||||

|

Exciter voltage (DCV) |

0-512 (varies with current) |

|||||||||||||

|

Ore unloading water pressure (Mpa) |

0.2~0.4 |

|||||||||||||

|

Water consumption for unloading (m3/h) |

0.65~1.4 |

1.4~2.5 |

8~12 |

12~20 |

20~30 |

30~50 |

50~100 |

100~150 |

150~200 |

250~350 |

350~500 |

500~650 |

550~800 |

|

|

Larger part weight (t) |

2/3.2/4.5 |

2.5/3.2/4 |

3/4.2/5 |

4/6/6.8 |

6.5/12/15 |

8.5/15/17 |

20/24/28 |

24/26/28 |

33/36/39 |

50/52/55 |

68/75/85 |

70/78/82 |

78/80/85 |

|

|

Overall dimension (mm) |

Long |

1650 |

2000 |

2650 |

2880 |

3430 |

3320 |

4200 |

3660 |

4410 |

4900 |

5470 |

5980 |

7000 |

|

1800 |

2600 |

2850 |

3420 |

3600 |

3980 |

4350 |

5100 |

5030 |

6490 |

6200 |

6160 |

7500 |

||

|

1950 |

2900 |

2520 |

3580 |

3750 |

4120 |

4650 |

5400 |

5590 |

7000 |

6930 |

6270 |

8000 |

||

|

Wide |

1500 |

2270 |

2350 |

2900 |

3680 |

3800 |

4690 |

4690 |

5540 |

5500 |

6240 |

6630 |

8100 |

|

|

1800 |

2860 |

3000 |

3280 |

3850 |

4260 |

4870 |

5930 |

5650 |

7000 |

7500 |

7830 |

8300 |

||

|

2000 |

3200 |

3600 |

3650 |

4350 |

4770 |

4950 |

5520 |

5780 |

8200 |

8760 |

7210 |

8600 |

||

|

High |

1250 |

2100 |

2450 |

2860 |

3410 |

3800 |

4150 |

5290 |

6450 |

6950 |

8400 |

9200 |

9400 |

|

|

1320 |

2400 |

2630 |

3000 |

3650 |

4130 |

4300 |

5450 |

6500 |

7400 |

8600 |

9480 |

9650 |

||

|

1550 |

2600 |

2490 |

3300 |

3800 |

4300 |

4510 |

5760 |

6550 |

7950 |

8900 |

9600 |

9800 |

||

Successful Cases

GUOTE MINING

Your reliable supplier

Mine Purification Equipment Engineering Laboratory. The company's products have passed ISO9001 quality system certification, environmental management system certification, occupational health and safety management system certification, EU ce certification, and dozens of national patents. Products are exported to South Korea, India, Southeast Asia, Africa and other countries and regions.

Get A Quote

If you have any questions, please feel free to leave us a message at any time