Single drum dryer

Guote GHG dryer is widely used in building materials, metallurgy, chemical industry, cement industry drying slag limestone

- Product Description

- Advantage Features

- Working principle

- Technical parameters

- Successful Cases

-

- Commodity name: Single drum dryer

Guote GHG dryer is widely used in building materials, metallurgy, chemical industry, cement industry drying slag limestone

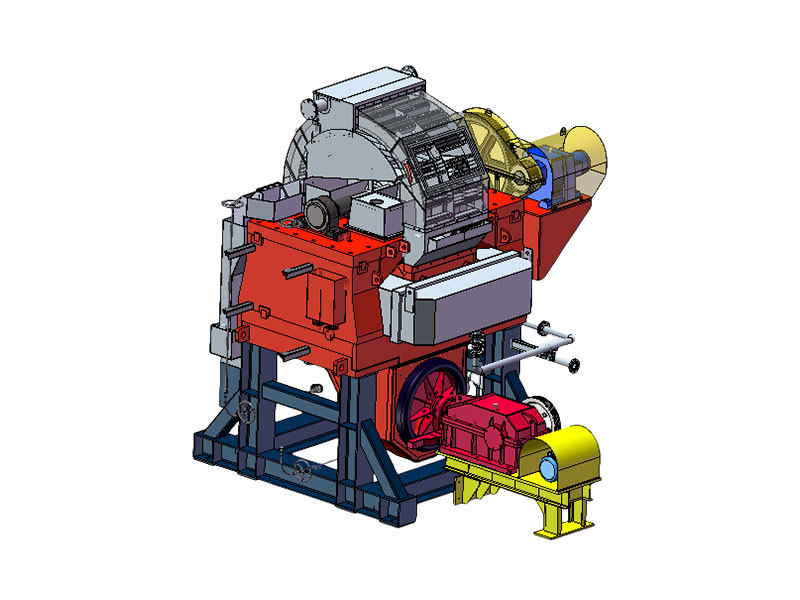

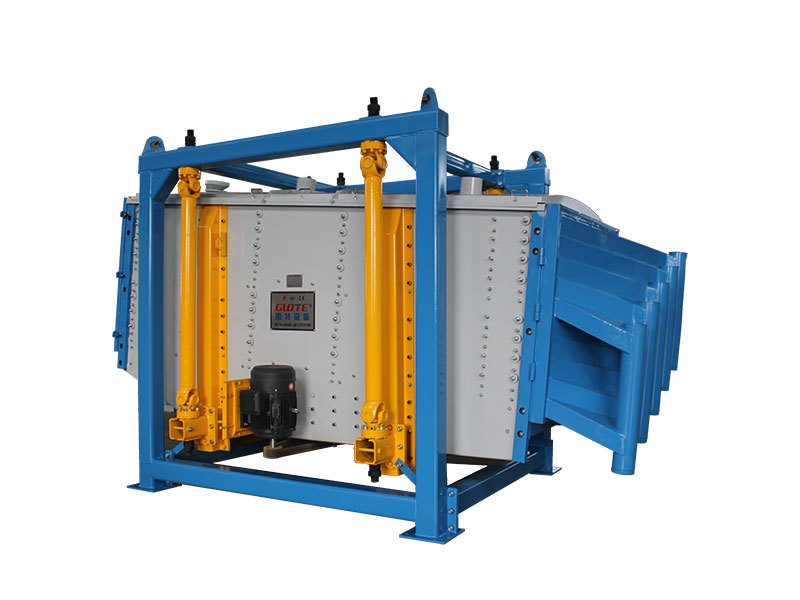

Guote GHG dryer is widely used in building materials, metallurgy, chemical industry, cement industry drying slag limestone, coal powder, slag, clay and other materials, mining dryer is mainly composed of rotary cylinder, material plate, transmission device, supporting device and sealing ring and other components. It has the advantages of reasonable structure, high output, low energy consumption and convenient operation.

Application areas:

Guote GHG dryer is widely used in building materials, metallurgy, chemical industry, cement industry drying slag limestone, coal powder, slag, clay and other materials. -

1. The whole production line is equipped with high temperature resistant environmental protection dust collector, and there is no dust and pollutant emission in the whole production process.

2. The whole set of equipment has simple and reasonable structure, convenient operation, low failure rate and convenient maintenance.

3, the heat source can use biomass raw materials or natural gas, high thermal efficiency, environmental protection and no pollution.

4. There is a material raising device inside, so that the material is evenly dispersed, which is conducive to water evaporation and external heat preservation.

5. The dryer cylinder is made 304 stainless steel welding, high purity and no pollution. -

Wet materials are sent to the hopper by belt conveyor or bucket elevator, and then enter the feeding end through the feeding pipe through the feeding machine of the hopper. The slope of the feeding pipe should be greater than the natural inclination of the material, so that the material can flow into the dryer smoothly. The dryer drum is a rotating drum that is slightly inclined to the horizontal. The material is added from the higher end, the heat carrier enters from the lower end and makes countercurrent contact with the material. There are also heat carriers and materials that enter the cylinder downstream together. A copy plate is installed on the inner wall of the cylinder. Its function is to copy up and scatter the material, so as to increase the contact surface between the material and the air flow, so as to improve the drying rate and promote the advancement of the material. The dried material falls onto the conveyor belt through the discharge port and is driven into the finished product bin.

-

Model

GHG1310

GHG1512

GHG1816

GHG2016

GHG2218

GHG2418

GHG2822

Diameter of outer cylinder (m)

1.3

1.5

1.8

2.0

2.2

2.4

2.8

Length of outer cylinder (m)

10

12

16

16

18

18

22

Barrel speed (rpm)

2-6

Initial moisture of material (%)

6-12

Final moisture of material (%)

≤ 1

Higher intake air temperature (℃)

750-900 ℃

Production capacity (t/h)

6-10

10-13

15-20

20-25

25-30

30-35

40-50

Motor power (kw)

16

18.5

22

30

37

45

75

-

Product Description

Guote GHG dryer is widely used in building materials, metallurgy, chemical industry, cement industry drying slag limestone, coal powder, slag, clay and other materials, mining dryer is mainly composed of rotary cylinder, material plate, transmission device, supporting device and sealing ring and other components. It has the advantages of reasonable structure, high output, low energy consumption and convenient operation.

Application areas:

Guote GHG dryer is widely used in building materials, metallurgy, chemical industry, cement industry drying slag limestone, coal powder, slag, clay and other materials.

Advantage Features

1. The whole production line is equipped with high temperature resistant environmental protection dust collector, and there is no dust and pollutant emission in the whole production process.

2. The whole set of equipment has simple and reasonable structure, convenient operation, low failure rate and convenient maintenance.

3, the heat source can use biomass raw materials or natural gas, high thermal efficiency, environmental protection and no pollution.

4. There is a material raising device inside, so that the material is evenly dispersed, which is conducive to water evaporation and external heat preservation.

5. The dryer cylinder is made 304 stainless steel welding, high purity and no pollution.

Working principle

Wet materials are sent to the hopper by belt conveyor or bucket elevator, and then enter the feeding end through the feeding pipe through the feeding machine of the hopper. The slope of the feeding pipe should be greater than the natural inclination of the material, so that the material can flow into the dryer smoothly. The dryer drum is a rotating drum that is slightly inclined to the horizontal. The material is added from the higher end, the heat carrier enters from the lower end and makes countercurrent contact with the material. There are also heat carriers and materials that enter the cylinder downstream together. A copy plate is installed on the inner wall of the cylinder. Its function is to copy up and scatter the material, so as to increase the contact surface between the material and the air flow, so as to improve the drying rate and promote the advancement of the material. The dried material falls onto the conveyor belt through the discharge port and is driven into the finished product bin.

Technical parameters

|

Model |

GHG1310 |

GHG1512 |

GHG1816 |

GHG2016 |

GHG2218 |

GHG2418 |

GHG2822 |

|

Diameter of outer cylinder (m) |

1.3 |

1.5 |

1.8 |

2.0 |

2.2 |

2.4 |

2.8 |

|

Length of outer cylinder (m) |

10 |

12 |

16 |

16 |

18 |

18 |

22 |

|

Barrel speed (rpm) |

2-6 |

||||||

|

Initial moisture of material (%) |

6-12 |

||||||

|

Final moisture of material (%) |

≤ 1 |

||||||

|

Higher intake air temperature (℃) |

750-900 ℃ |

||||||

|

Production capacity (t/h) |

6-10 |

10-13 |

15-20 |

20-25 |

25-30 |

30-35 |

40-50 |

|

Motor power (kw) |

16 |

18.5 |

22 |

30 |

37 |

45 |

75 |

Successful Cases

GUOTE MINING

Your reliable supplier

Mine Purification Equipment Engineering Laboratory. The company's products have passed ISO9001 quality system certification, environmental management system certification, occupational health and safety management system certification, EU ce certification, and dozens of national patents. Products are exported to South Korea, India, Southeast Asia, Africa and other countries and regions.

Get A Quote

If you have any questions, please feel free to leave us a message at any time