Three-drum dryer

The three-cylinder dryer improves the internal structure of the original single-cylinder dryer

- Product Description

- Advantage Features

- Working principle

- Technical parameters

- Successful Cases

-

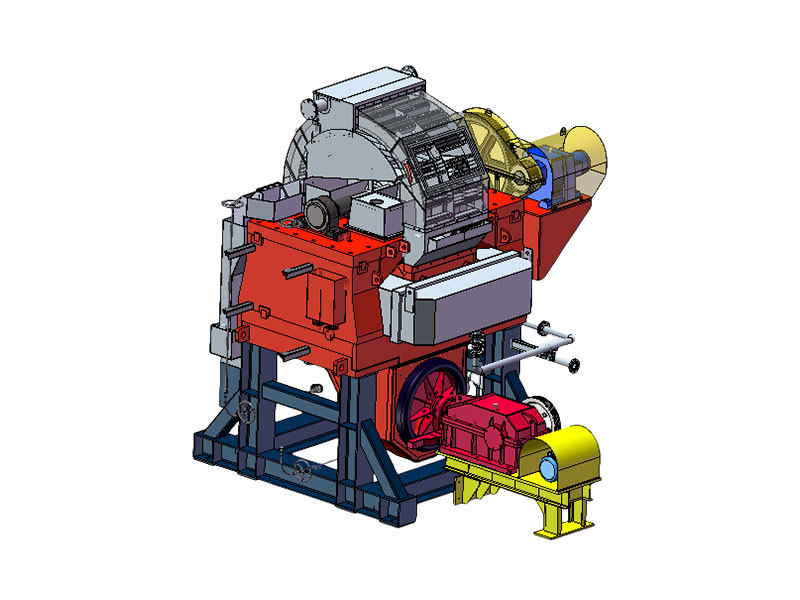

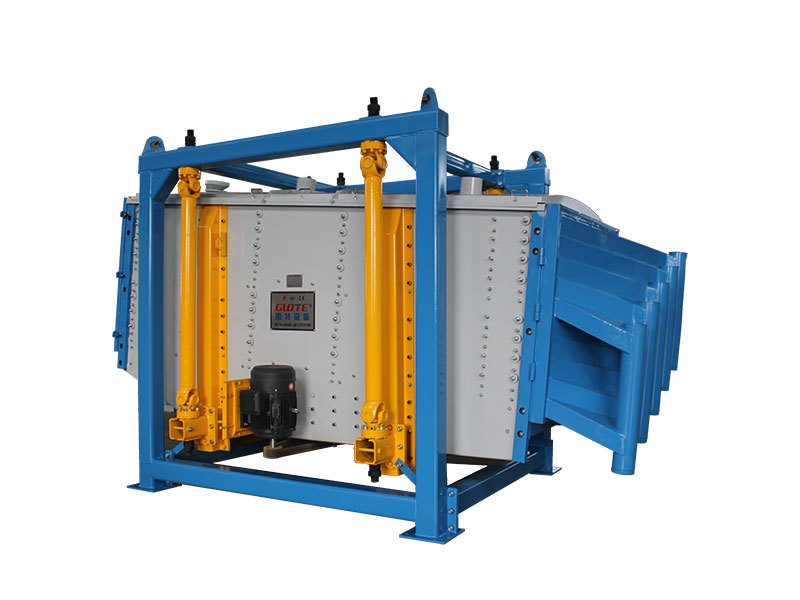

- Commodity name: Three-drum dryer

The three-cylinder dryer improves the internal structure of the original single-cylinder dryer

The three-cylinder dryer improves the internal structure of the original single-cylinder dryer, increases the pre-drying of wet materials before entering the dryer and prolongs the drying time of wet materials in the dryer, coupled with sealing, heat preservation and reasonable supporting measures, the production capacity of the dryer is increased by 48-80% compared with the original single-cylinder dryer, the evaporation intensity per unit volume can reach 120-180kg/m3, and the standard coal consumption is only 6-8 kg/t. Its advanced technology, reasonable operating parameters, simple and feasible operation.

Application areas:

Three cylinder dryer equipment can dry mortar, sand, cement plant slag, clay, quartz sand, coal gangue, mixture, fly ash, gypsum, iron powder and other raw materials drying, widely used in building materials, chemical industry, casting and other industries. -

1. The machine adopts material and hot air flow downstream drying process, and has a wide range of applications.

2. The final moisture index can be easily regulated according to user requirements.

3. The fuel can be adapted to coal, oil and gas, and can bake blocks, granules and powdery materials below 20-40mm.

4. Compared with single-cylinder dryer, three-cylinder dryer can reduce the occupied area by about 50%, and the civil construction investment can be reduced by about 50%.The thermal efficiency of the three-cylinder dryer is as high as 80%, and the thermal efficiency is increased by 48%.

6, the material can be customized according to the needs of 304, 316 stainless steel, ultra pure production, to eliminate impurity pollution.

7. The equipment investment of the three-cylinder dryer is 1/6 of that of imported products. It is made of alloy steel plate, which is 3-4 times more wear-resistant than ordinary steel plate.

-

The material enters the inner layer of the rotary drum of the three-cylinder dryer from the feeding device to realize downstream drying. The material is continuously picked up and scattered under the copy board of the inner layer to realize heat exchange in a spiral pattern. The material moves to the other end of the inner layer and enters the middle layer for counter-current drying. The material is continuously pushed in and out in the middle layer, in a two-step and one-step-step traveling mode, it also absorbs the heat of the middle layer drum, and at the same time prolongs the drying time, and the material reaches a good dry state here.

-

Model

GHS2245

GHS2506

GHS2807

GHS3007

GHS3208

GHS3609

Diameter of outer cylinder m

2.2

2.5

2.8

3

3.2

3.6

Outer cylinder length m

4.5

6

7

7

8

8

Barrel speed rpm

4-10

Motor power kw

3*2

5.5*2

7.5*2

22*4

37*4

55*4

Machine weight t

6

7.4

15.3

32

43

48

Initial moisture%

6-12

Final moisture%

1

Maximum intake air temperature ℃

700-750 ℃

Production capacity T/h

Quartz sand 10-15

Quartz sand 20-25

Quartz sand 30-35

Quartz sand 35-45

Quartz sand 50-60

Quartz sand 60-75

-

Product Description

The three-cylinder dryer improves the internal structure of the original single-cylinder dryer, increases the pre-drying of wet materials before entering the dryer and prolongs the drying time of wet materials in the dryer, coupled with sealing, heat preservation and reasonable supporting measures, the production capacity of the dryer is increased by 48-80% compared with the original single-cylinder dryer, the evaporation intensity per unit volume can reach 120-180kg/m3, and the standard coal consumption is only 6-8 kg/t. Its advanced technology, reasonable operating parameters, simple and feasible operation.

Application areas:

Three cylinder dryer equipment can dry mortar, sand, cement plant slag, clay, quartz sand, coal gangue, mixture, fly ash, gypsum, iron powder and other raw materials drying, widely used in building materials, chemical industry, casting and other industries.

Advantage Features

1. The machine adopts material and hot air flow downstream drying process, and has a wide range of applications.

2. The final moisture index can be easily regulated according to user requirements.

3. The fuel can be adapted to coal, oil and gas, and can bake blocks, granules and powdery materials below 20-40mm.

4. Compared with single-cylinder dryer, three-cylinder dryer can reduce the occupied area by about 50%, and the civil construction investment can be reduced by about 50%.

The thermal efficiency of the three-cylinder dryer is as high as 80%, and the thermal efficiency is increased by 48%.

6, the material can be customized according to the needs of 304, 316 stainless steel, ultra pure production, to eliminate impurity pollution.

7. The equipment investment of the three-cylinder dryer is 1/6 of that of imported products. It is made of alloy steel plate, which is 3-4 times more wear-resistant than ordinary steel plate.

Working principle

The material enters the inner layer of the rotary drum of the three-cylinder dryer from the feeding device to realize downstream drying. The material is continuously picked up and scattered under the copy board of the inner layer to realize heat exchange in a spiral pattern. The material moves to the other end of the inner layer and enters the middle layer for counter-current drying. The material is continuously pushed in and out in the middle layer, in a two-step and one-step-step traveling mode, it also absorbs the heat of the middle layer drum, and at the same time prolongs the drying time, and the material reaches a good dry state here.

Technical parameters

|

Model |

GHS2245 |

GHS2506 |

GHS2807 |

GHS3007 |

GHS3208 |

GHS3609 |

|

Diameter of outer cylinder m |

2.2 |

2.5 |

2.8 |

3 |

3.2 |

3.6 |

|

Outer cylinder length m |

4.5 |

6 |

7 |

7 |

8 |

8 |

|

Barrel speed rpm |

4-10 |

|||||

|

Motor power kw |

3*2 |

5.5*2 |

7.5*2 |

22*4 |

37*4 |

55*4 |

|

Machine weight t |

6 |

7.4 |

15.3 |

32 |

43 |

48 |

|

Initial moisture% |

6-12 |

|||||

|

Final moisture% |

1 |

|||||

|

Maximum intake air temperature ℃ |

700-750 ℃ |

|||||

|

Production capacity T/h |

Quartz sand 10-15 |

Quartz sand 20-25 |

Quartz sand 30-35 |

Quartz sand 35-45 |

Quartz sand 50-60 |

Quartz sand 60-75 |

Successful Cases

GUOTE MINING

Your reliable supplier

Mine Purification Equipment Engineering Laboratory. The company's products have passed ISO9001 quality system certification, environmental management system certification, occupational health and safety management system certification, EU ce certification, and dozens of national patents. Products are exported to South Korea, India, Southeast Asia, Africa and other countries and regions.

Get A Quote

If you have any questions, please feel free to leave us a message at any time