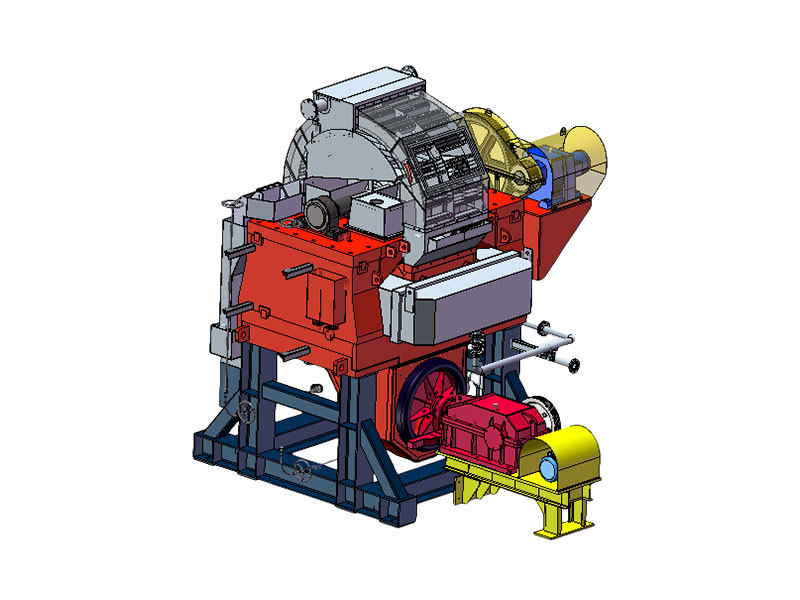

Dry roller magnetic separator

Particles or coarse powder materials clear weak magnetic impurities, used in ceramics, glass

- Product Description

- Advantage Features

- Working principle

- Technical parameters

- Successful Cases

-

- Commodity name: Dry roller magnetic separator

Particles or coarse powder materials clear weak magnetic impurities, used in ceramics, glass

Particles or coarse powder materials clear weak magnetic impurities, used in ceramics, glass, refractory materials, abrasives and other non-metallic minerals, chemical, food, biological purification, and hematite, limonite and other weak magnetic ore dry pre-selection, dry beneficiation of manganese ore.

Application areas:

Ceramics, glass, refractory materials, abrasives and limonite and other weak magnetic ore dry pre-selection, dry pre-selection of manganese ore. -

1, the equipment has a dust removal port, dust concentrated emission, to meet the requirements of environmental protection.

2, automatic cleaning of weak magnetic oxide, can guarantee long time trouble-free operation.

3. The controllable feeding system ensures the uniformity of the material when flowing through the magnetic field area. The conveyor belt used by the magnetic roller is made of special materials with good wear resistance.

4. The magnetic roller adopts the magnetic composite magnetic system, the magnetic field strength can reach 15000GS, and the gradient is higher.

5. The magnetic system of the magnetic cylinder can be made into a turning type, the removal rate is greatly improved, and the rotation speed of the drum and the magnetic roller can be adjusted by frequency conversion to meet the requirements of wider particle size and output.

6. The drum adopts a new type of compensation magnetic type magnetic system, the magnetic field strength can reach 8000GS, the magnetic field strength is higher, and the suction force is stronger.7. The reasonable combination of permanent magnet cylinder and permanent magnet roller has better iron removal effect.

-

GCT/F3-I

300

15000-20000

4000-10000

0.1-2

83-5000

0.4-0.6

0.75*2

0.55*1

GCT/F3-II

0.55*2

GCT/F5-I

500

15000-20000

4000-10000

0.1-2

83-5000

0.8-1

0.75*2

0.55*1

GCT/F5-II

0.55*2

GCT/F8-I

800

15000-20000

4000-10000

0.1-2

83-5000

1.2-2

1.1*2

0.55*1

GCT/F8-II

0.55*2

GCT/F10-I

1000

15000-20000

4000-10000

0.1-2

83-5000

2-3.5

1.5*2

0.55*1

GCT/F10-II

0.55*2

GCT/F12-I

1200

15000-20000

4000-10000

0.1-2

83-5000

4-7

2.2*2

0.55*1

GCT/F12-II

0.55*2

GCT/F15-I

1500

15000-20000

4000-10000

0.1-2

83-5000

7-10

3*2

0.55*1

GCT/F15-II

0.55*2

-

Product Description

Particles or coarse powder materials clear weak magnetic impurities, used in ceramics, glass, refractory materials, abrasives and other non-metallic minerals, chemical, food, biological purification, and hematite, limonite and other weak magnetic ore dry pre-selection, dry beneficiation of manganese ore.

Application areas:

Ceramics, glass, refractory materials, abrasives and limonite and other weak magnetic ore dry pre-selection, dry pre-selection of manganese ore.

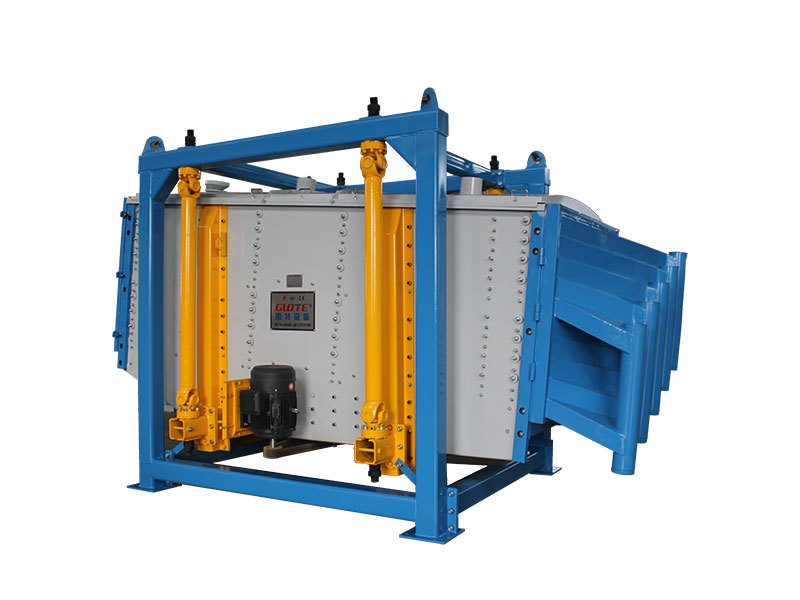

Advantage Features

1, the equipment has a dust removal port, dust concentrated emission, to meet the requirements of environmental protection.

2, automatic cleaning of weak magnetic oxide, can guarantee long time trouble-free operation.

3. The controllable feeding system ensures the uniformity of the material when flowing through the magnetic field area. The conveyor belt used by the magnetic roller is made of special materials with good wear resistance.

4. The magnetic roller adopts the magnetic composite magnetic system, the magnetic field strength can reach 15000GS, and the gradient is higher.

5. The magnetic system of the magnetic cylinder can be made into a turning type, the removal rate is greatly improved, and the rotation speed of the drum and the magnetic roller can be adjusted by frequency conversion to meet the requirements of wider particle size and output.

6. The drum adopts a new type of compensation magnetic type magnetic system, the magnetic field strength can reach 8000GS, the magnetic field strength is higher, and the suction force is stronger.

7. The reasonable combination of permanent magnet cylinder and permanent magnet roller has better iron removal effect.

Working principle

Technical parameters

|

GCT/F3-I |

300 |

15000-20000 |

4000-10000 |

0.1-2 |

83-5000 |

0.4-0.6 |

0.75*2 |

0.55*1 |

|

GCT/F3-II |

0.55*2 |

|||||||

|

GCT/F5-I |

500 |

15000-20000 |

4000-10000 |

0.1-2 |

83-5000 |

0.8-1 |

0.75*2 |

0.55*1 |

|

GCT/F5-II |

0.55*2 |

|||||||

|

GCT/F8-I |

800 |

15000-20000 |

4000-10000 |

0.1-2 |

83-5000 |

1.2-2 |

1.1*2 |

0.55*1 |

|

GCT/F8-II |

0.55*2 |

|||||||

|

GCT/F10-I |

1000 |

15000-20000 |

4000-10000 |

0.1-2 |

83-5000 |

2-3.5 |

1.5*2 |

0.55*1 |

|

GCT/F10-II |

0.55*2 |

|||||||

|

GCT/F12-I |

1200 |

15000-20000 |

4000-10000 |

0.1-2 |

83-5000 |

4-7 |

2.2*2 |

0.55*1 |

|

GCT/F12-II |

0.55*2 |

|||||||

|

GCT/F15-I |

1500 |

15000-20000 |

4000-10000 |

0.1-2 |

83-5000 |

7-10 |

3*2 |

0.55*1 |

|

GCT/F15-II |

0.55*2 |

Successful Cases

GUOTE MINING

Your reliable supplier

Mine Purification Equipment Engineering Laboratory. The company's products have passed ISO9001 quality system certification, environmental management system certification, occupational health and safety management system certification, EU ce certification, and dozens of national patents. Products are exported to South Korea, India, Southeast Asia, Africa and other countries and regions.

Get A Quote

If you have any questions, please feel free to leave us a message at any time