Pulse bag dust collector

The products are widely used in construction, chemistry, metallurgy, non-metal mining, food, grinding materials

- Product Description

- Advantage Features

- Working principle

- Technical parameters

- Successful Cases

-

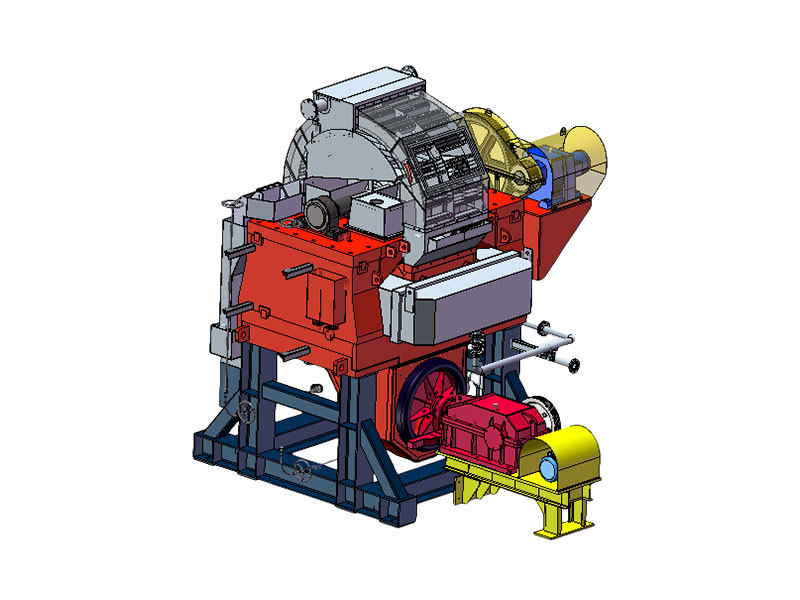

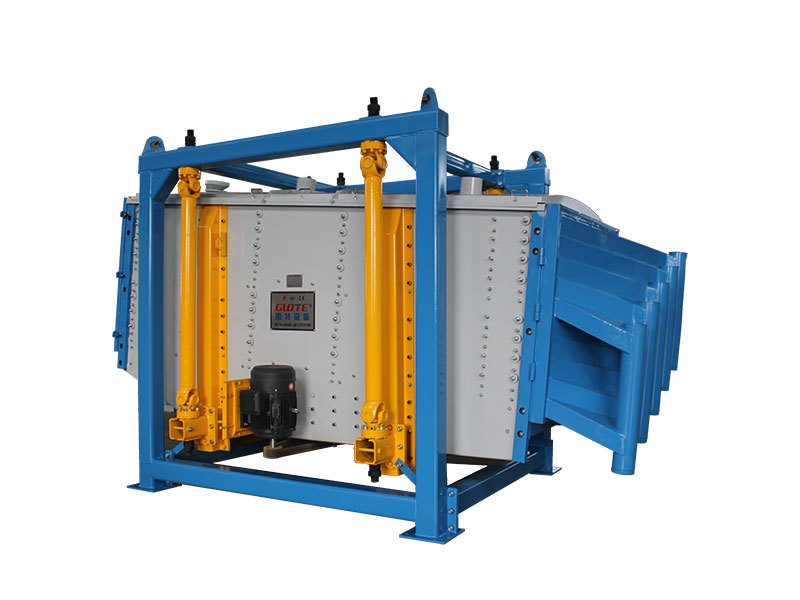

- Commodity name: Pulse bag dust collector

The products are widely used in construction, chemistry, metallurgy, non-metal mining, food, grinding materials

The products are widely used in construction, chemistry, metallurgy, non-metal mining, food, grinding materials, plastics and some new materials, which is an ideal dust collection equipment in industry and environmental protection.

Application areas:

This product is widely used in cement, mineral processing, electronics, chemicals, food processing, metallurgy, casting, carbon materials, mechanical processing, wood building materials and other industries. -

1, according to the working conditions of the environment, the selection of different performance, specifications of the filter material, stable running resistance, low energy consumption, dust removal efficiency of more than 99.9%.

2. The outer surface is smooth and without welding marks, which solves the wear phenomenon of the filter bag and the frame, and the filter bag has a long service life.

3. The filter bag mouth is sealed with elastic expansion ring, with good tightness and convenient disassembly and assembly. Resistance welding for frames.

4. At the same time, it has the effect of coagulation and sedimentation, reducing the filter bag load and pulse frequency.

5, the airflow combination is reasonable, the use of downstream airflow, downstream filtration, so that the dust in the filtered state. -

The dust-containing gas enters the middle and lower boxes from the air inlet of the dust collector, and the dust and gas are separated by the filtering effect of the filter bag. The dust is adsorbed on the surface of the filter bag, and the clean air is discharged from the air outlet through the filter bag. As time increases, more and more dust is accumulated on the surface of the filter bag. According to the setting of the pulse blowing program, the pulse blowing valve receives the instructions issued by the control instrument and triggers the opening in sequence. The compressed air in the air bag is instantly sprayed from each hole of the spray pipe, and sprayed into each corresponding filter bag through the venturi tube. The dust adsorbed on the surface of the filter bag falls off, falls into the ash hopper, and is discharged through the ash discharge valve or directly falls into the bin.

-

Model

MDC-60

MDC-72

MDC-84

MDC-96

MDC-108

MDC-120

MDC-124

MDC-168

MDC-200

Filtration area (m)

50

60

70

81

91

102

120

142

170

Number of filter bags (pcs)

60

72

84

96

108

120

140

168

200

Filter bag specification (mm)

Φ130*2000

Working temperature (℃)

<120 (polyester)

Equipment resistance (Pa)

1000-1500

Dust removal efficiency (%)

<99

Inlet dust concentration (mg/m³)

<15

Filtration wind speed (m/min)

1-1.2

Treated air volume (m/h)

5800-8200

7200-9960

8400-12000

9720-13446

10800-15000

12200-17200

14400-19900

17300-23570

20400-28300

Injection pressure (Pa)

0.5-0.7

Pulse solenoid valve (unit)

4

6

8

10

12

14

16

18

20

Pulse width (S)

0.1-0.2

Pulse period ()

60-120

Pulse Interval (s)

1-5

Overall dimension (mm)

1100*1685*2527

1500*1685*2527

1900*1685*2527

2300*1685*2527

2700*1685*2527

3100*1685*2527

3600*1685*2527

4000*1685*2527

4400*1685*2527

-

Product Description

The products are widely used in construction, chemistry, metallurgy, non-metal mining, food, grinding materials, plastics and some new materials, which is an ideal dust collection equipment in industry and environmental protection.

Application areas:

This product is widely used in cement, mineral processing, electronics, chemicals, food processing, metallurgy, casting, carbon materials, mechanical processing, wood building materials and other industries.

Advantage Features

1, according to the working conditions of the environment, the selection of different performance, specifications of the filter material, stable running resistance, low energy consumption, dust removal efficiency of more than 99.9%.

2. The outer surface is smooth and without welding marks, which solves the wear phenomenon of the filter bag and the frame, and the filter bag has a long service life.

3. The filter bag mouth is sealed with elastic expansion ring, with good tightness and convenient disassembly and assembly. Resistance welding for frames.

4. At the same time, it has the effect of coagulation and sedimentation, reducing the filter bag load and pulse frequency.

5, the airflow combination is reasonable, the use of downstream airflow, downstream filtration, so that the dust in the filtered state.

Working principle

The dust-containing gas enters the middle and lower boxes from the air inlet of the dust collector, and the dust and gas are separated by the filtering effect of the filter bag. The dust is adsorbed on the surface of the filter bag, and the clean air is discharged from the air outlet through the filter bag. As time increases, more and more dust is accumulated on the surface of the filter bag. According to the setting of the pulse blowing program, the pulse blowing valve receives the instructions issued by the control instrument and triggers the opening in sequence. The compressed air in the air bag is instantly sprayed from each hole of the spray pipe, and sprayed into each corresponding filter bag through the venturi tube. The dust adsorbed on the surface of the filter bag falls off, falls into the ash hopper, and is discharged through the ash discharge valve or directly falls into the bin.

Technical parameters

|

Model |

MDC-60 |

MDC-72 |

MDC-84 |

MDC-96 |

MDC-108 |

MDC-120 |

MDC-124 |

MDC-168 |

MDC-200 |

|

Filtration area (m) |

50 |

60 |

70 |

81 |

91 |

102 |

120 |

142 |

170 |

|

Number of filter bags (pcs) |

60 |

72 |

84 |

96 |

108 |

120 |

140 |

168 |

200 |

|

Filter bag specification (mm) |

Φ130*2000 |

||||||||

|

Working temperature (℃) |

<120 (polyester) |

||||||||

|

Equipment resistance (Pa) |

1000-1500 |

||||||||

|

Dust removal efficiency (%) |

<99 |

||||||||

|

Inlet dust concentration (mg/m³) |

<15 |

||||||||

|

Filtration wind speed (m/min) |

1-1.2 |

||||||||

|

Treated air volume (m/h) |

5800-8200 |

7200-9960 |

8400-12000 |

9720-13446 |

10800-15000 |

12200-17200 |

14400-19900 |

17300-23570 |

20400-28300 |

|

Injection pressure (Pa) |

0.5-0.7 |

||||||||

|

Pulse solenoid valve (unit) |

4 |

6 |

8 |

10 |

12 |

14 |

16 |

18 |

20 |

|

Pulse width (S) |

0.1-0.2 |

||||||||

|

Pulse period () |

60-120 |

||||||||

|

Pulse Interval (s) |

1-5 |

||||||||

|

Overall dimension (mm) |

1100*1685*2527 |

1500*1685*2527 |

1900*1685*2527 |

2300*1685*2527 |

2700*1685*2527 |

3100*1685*2527 |

3600*1685*2527 |

4000*1685*2527 |

4400*1685*2527 |

Successful Cases

GUOTE MINING

Your reliable supplier

Mine Purification Equipment Engineering Laboratory. The company's products have passed ISO9001 quality system certification, environmental management system certification, occupational health and safety management system certification, EU ce certification, and dozens of national patents. Products are exported to South Korea, India, Southeast Asia, Africa and other countries and regions.

Get A Quote

If you have any questions, please feel free to leave us a message at any time